Cases

📧:Leon@harlytech.cn/

What's Ceramic Heating Pad

The ceramic heater is applicable to various metal components, such as large towers, high-pressure vessels, bridges, welding preheating of high-pressure pipelines, and post-welding stress relief, and can also be used for chemical pipelines, vessels and other auxiliary heating.

Various Styles

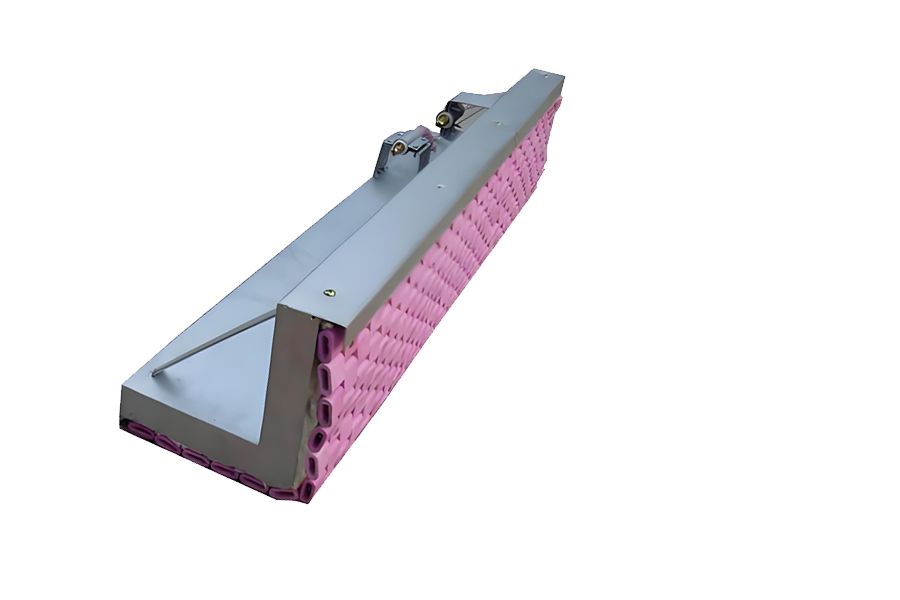

Crawler Ceramic Heater

Made of high-quality nickel-chromium alloy wire and cable, the outer set of high-purity alumina ceramic insulation parts is made into the body of Pad. The length and width can be changed flexibly and produced according to the shape and size of the workpiece

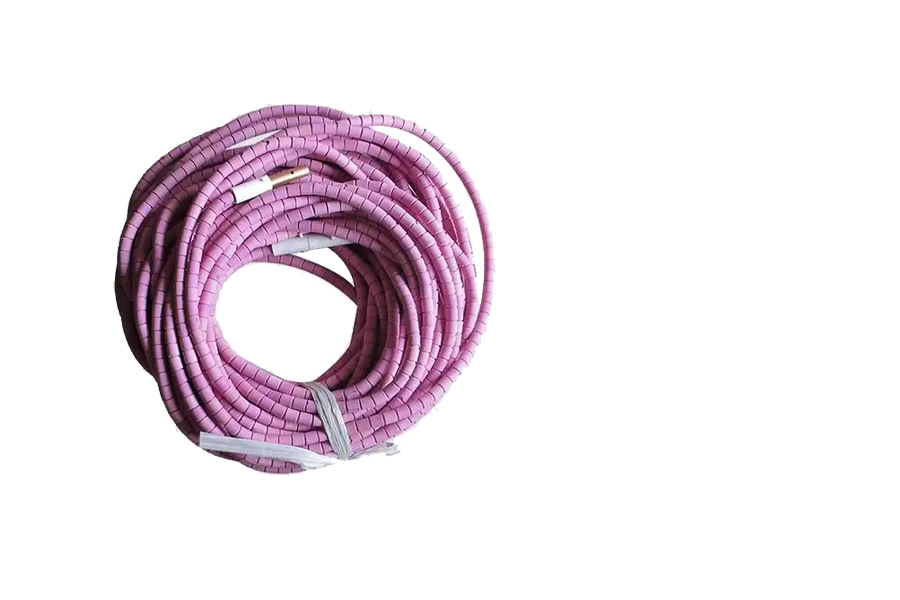

Rope-type Ceramic Heater

For pipelines, pipe joints, angled pipes, and workpieces of various shapes, the narrow space makes it challenging to work around. A rope heater is particularly suitable for pipe joint heat treatment, boiler tube mouth heat treatment, etc.

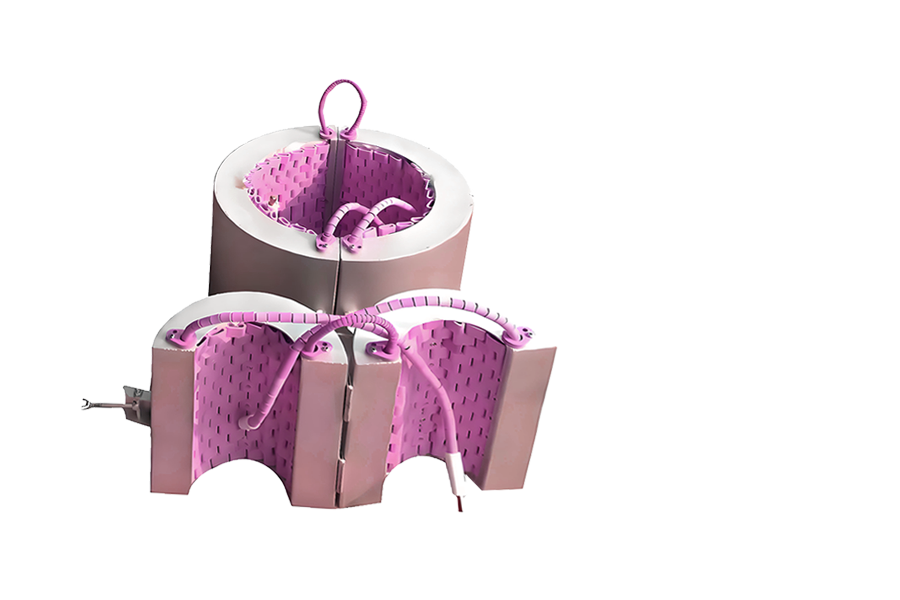

Folio Type Ceramic Heater

With a pad heater as a heat source, coupled with insulation Paderial and a shell made into a circle-type folio heater, it is easy to install and disassemble. This is suitable for the local heating of small pipelines

Adsorption Ceramic Heater

The pad heater with a shell is installed with several magnets on both sides, which can be attached to the workpiece during heating. It is suitable for preheating metal components such as spherical tanks and ship hulls before welding. It is flexible and convenient to use.

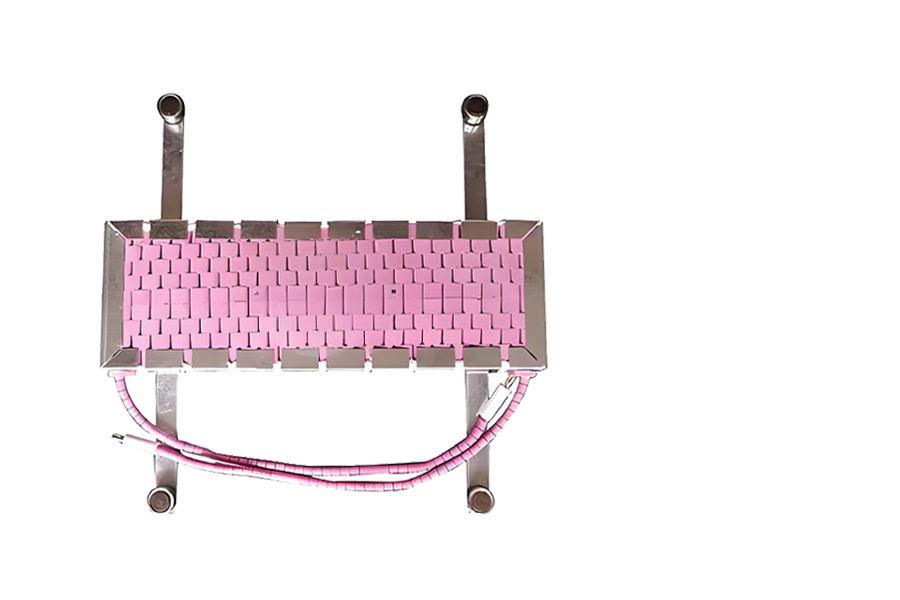

Frame Type Ceramic Heater

The heater is made of a high-resistance alloy belt as a heating element, fast temperature rise, long life, and low voltage heating safety. Combined with other tooling, it can radiate heat to rotating workpieces

Right Angle Ceramic Heater

Using a crawler ceramic heater as the heat source, combined with insulation material and shell, a right angled heater is made for easy loading and unloading, suitable for local heating of internal and external corner welds

Industry Applications

Power Plant

Suitable for heat treatment before and after welding of steam pipelines in power plants

Oil Refinery

Suitable for heat treatment before and after welding of oil pipelines in refineries

Metallurgical Plant

Suitable for heat treatment of metal materials before and after welding in metallurgical plants

Machinery Plant

Suitable for heat treatment of metal structural components before and after welding in mechanical factories

Ship Plant

Suitable for heat treatment before and after welding of ship metal structures in shipyards

Chemical Plant

Suitable for heat treatment of pressure vessels before and after welding in chemical plants

Advantages

Located in the center of the heater industry

Our city produces 80% of the world's welding heating equipment and has a well-established supply chain

Harlytech quality, leading technology

We have always focused on the research and production of heat treatment equipment, accumulating rich experience

ISO9001 quality system certification

Fully implement the international advanced quality management system to ensure the quality

7 * 12 hour reliable service

This includes timely tracking of goods delivery, commissioning of heat treatment machine, and operator telephone guidance

Focused on welding heat treatment equipment

Excellent manufacturers from China, the choice of over 10000 industry customers